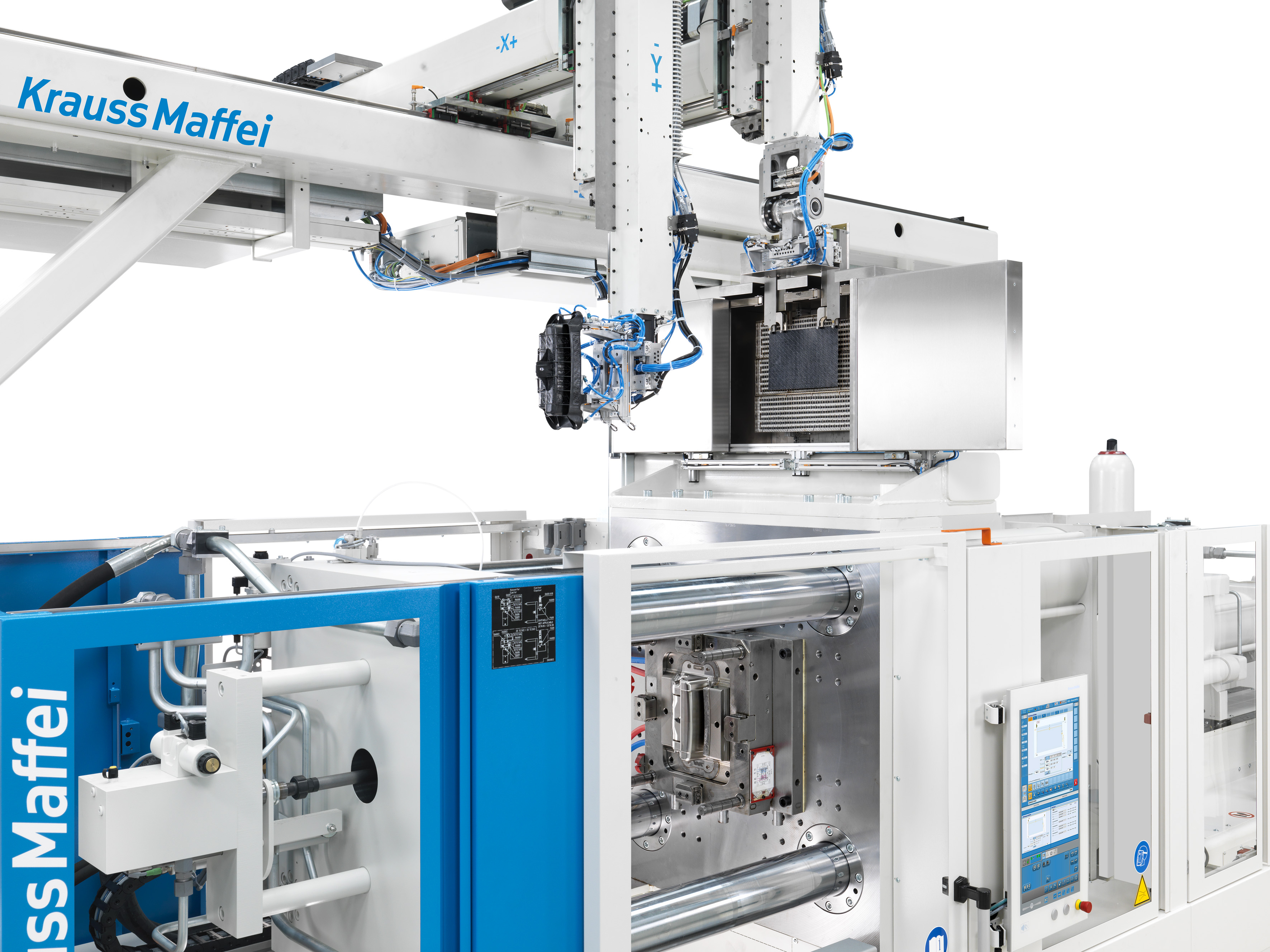

For many years, KraussMaffei has been working with widely varying processes for manufacturing parts made of fiber-reinforced plastic (FRP). These processes have traditionally evolved from injection molding technology and reaction technology (PU). Today our process portfolio ranges from injection molding of components with short-glass-fiber reinforcement to high-strength, lightweight parts with a complex mesh structure in a reactive matrix. We set the highest priority on manufacturing processes that are automation-capable.

Within the multi-functional processing technology called FiberForm, injection molding is combined with thermoforming of composite sheets to further improve the strength of fiber-reinforced plastic parts. This is used to form seat shells and backs, instrument panel carriers, box cover, side impact protection components, technical, underhood components and semi-structural components. This opens up infinite potential for functional integration and part design since FiberForm can be combined with almost all special processes.

More information on the following topics:

Ready for download:

Brochure: “FiberForm Lightweight parts – the perfect combination of thermoforming and injection molding”

Joint development of products with organo sheet suppliers, tool makers and OEMs, especially within the Automotive industry.

Stefan Fenske

Technology Manager FiberForm & IMC

stefan.fenske@kraussmaffei.com

+49 89 8899 3231

KraussMaffei Technologies GmbH

Krauss-Maffei-Str. 2

80997 München

Germany

Dr.-Ing. Mesut Cetin

Product- und Projectmanager Composites

mesut.cetin@kraussmaffei.com

+49 8122 9782 317

KraussMaffei Automation GmbH

Möslstraße 19

85445 Oberding-Schwaig

Germany